Research & Development

Continuous innovation to turn ideas into concrete solutions

What do we develop?

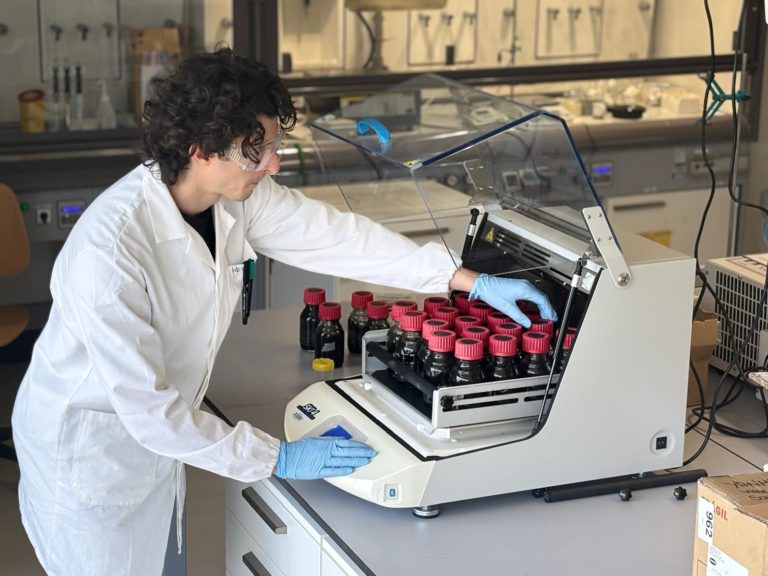

Our R&D department is the beating heart of HBI projects. Here we develop proprietary technologies and applied solutions to address some of today's major environmental challenges:

Water reuse models for the reuse of purified wastewater, developed in accordance with European regulations and designed to respond concretely to the environmental, industrial and agricultural needs of the territories.

Integrated systems for sewage sludge recovery and valorization , with focus on material recovery, sustainable energy production, CRM valorization for circular fertilizer production.

Our strategic axes

Our research activity focuses on three strategic axes:

Circularity: turning by-products and waste into resources.

Operational sustainability: reduce impacts, improve performance.

Development of ready-to-market technologies: not laboratory prototypes, but solutions designed for industrial application, current regulations, and real market needs.

Innovation projects

Metal Removal (ERDF 1043)

Development and optimization of post-treatment for the removal of heavy metals from gasification ash, with the goal of recovering a phosphorus-rich agglomerate to be reused as a secondary raw material for sustainable fertilizer production.

Elimination of PFAS

Development and optimization of post-treatment for the removal of heavy metals from gasification ash, with the goal of recovering a phosphorus-rich agglomerate to be reused as a secondary raw material for sustainable fertilizer production.

Increased biogas production

Recirculation of bioavailable carbon to the anaerobic digester as a substrate to increase biogas production and promote energy neutrality of the sewage treatment plant.

Ammonia recovery (PNRR B2H2)

Recirculation of bioavailable carbon to the anaerobic digester as a substrate to increase biogas production and promote energy neutrality of the sewage treatment plant.

Industrial sludge

Extending the use of HBI technology for industrial sludge treatment, with performance analysis and evaluation of recovery potential.

End of waste

We aspire to close the sludge treatment loop by obtaining End-of-Waste status to valorize the ash as a source for sustainable fertilizers.